Sewer linings can help to repair cracked pipes without having to completely replace your sewer lines or destroy the area around them.

If you are looking to replace an existing underground sewer pipe that has started to leak, first consider your options. A full sewer pipe replacement may not be necessary. Often, relining your existing pipes is a better option. If your sewer lines are beneath trees, near extensive landscaping, sidewalks, driveways or other semi-permanent features, total sewer excavation can cause a great deal of collateral damage (and expense) to the surrounding area.

In many cases, pipe relining is great alternative to replacing your sewer pipes. There are four types of pipe relining systems to successfully get the job done. All the materials will rehabilitate the interior of your pipes without having to completely replace them.

Here are the types of pipe relining systems available today:

1. CURED-IN PLACE

Cured-in place piping is a method used to repair trenchless relining systems. Professional sewer and drain companies like Roto-Rooter are able to remotely line the section of the pipe that is cracked without having to dig a trench. After the interior of the pipe is cleaned and dried, the installers will apply the lining to the problem area. The liner is cured in place with jets of hot steam as it molds into all the cracks inside the pipe.

2. PULL-IN PLACE

Pull-in place is the best lining method for pipes that have larger gaps and cracks. The material is fixed into the pipe using heat, like steam. The epoxy-saturated liner is then pulled into place (the place being the area of the pipe that needs repair). To pull the liner through the desired location, two access points are needed: one to feed the liner and one to pull it through. Air is introduced into the pipe to open the sleeve and hold it against the inner walls of the pipe until it dries in place.

3. PIPE BURSTING

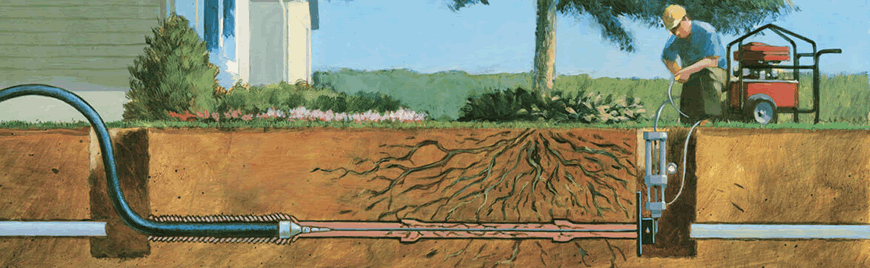

The pipe-bursting method is used on pipes that are severely damaged, for replacing an entire pipe system, or for repairing larger sections of sewer pipeline. The installers need physical access to the pipe in order to begin repair, which includes two four foot square access pits at either end of the pipeline. The installers begin by placing a “bursting head” at the access point on one end of the pipe. Hydraulic power is used to drag the head through the pipe. As it makes its way through the system, breaking the old pipe apart and drawing in a new seamless pipe behind it. The pipe is a plastic material that will be impervious to root intrusion for up to 100 years.

4. INTERNAL PIPE COATING

Professional installers use internal pipe coating to repair an existing sewer pipe that has started to leak into surrounding soil. To prepare the area for treatment, they will completely drain the pipes to get rid of any water. A thick epoxy coating is sprayed on the inside of your pipes to permanently seal the leaks and cracks throughout the pipeline.

All of these pipe relining techniques leave behind a smooth, seamless pipe that is designed to last for generations.

CALL THE PLUMBING PROFESSIONALS AT ROTO-ROOTER

Pipe relining requires the work of an experienced professional and is not a do-it-yourself job. For more information on sewer pipe replacement options, contact us today.